Spare and Wear Parts for Mining and Construction Equipment

About Us

Mining Element manufactures spare and wear parts under its own brand Element in accordance with ISO 9001 standard.

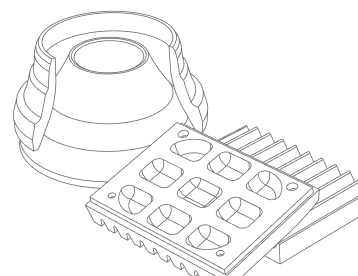

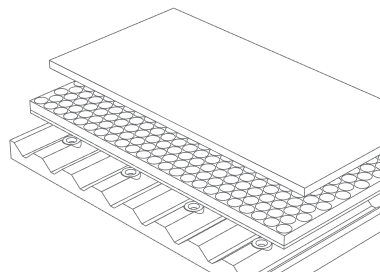

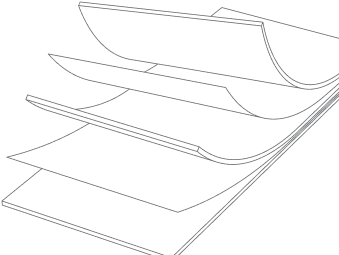

We develop and manufacture parts for crushing, screening, and pumping equipment, conveyor belts and components, wear-resistant materials for reloading devices, as well as linings for mills complete with fasteners. We supply components for underground equipment: LHDs, dump trucks and underground drilling rigs. All spare parts are fully compatible with the equipment of widely used brands in the mining and construction industries.

In addition to the production of standard components, Mining Element provides full technical support and offers services for the selection of analogues and modernization of spare parts for specific operating conditions.

What's new

Up to 50% Off Available DSO Parts

Mining Element is hosting a warehouse clearance sale! You can now order spare and wear parts for crushing and screening equipment at discounts of up to 50%.

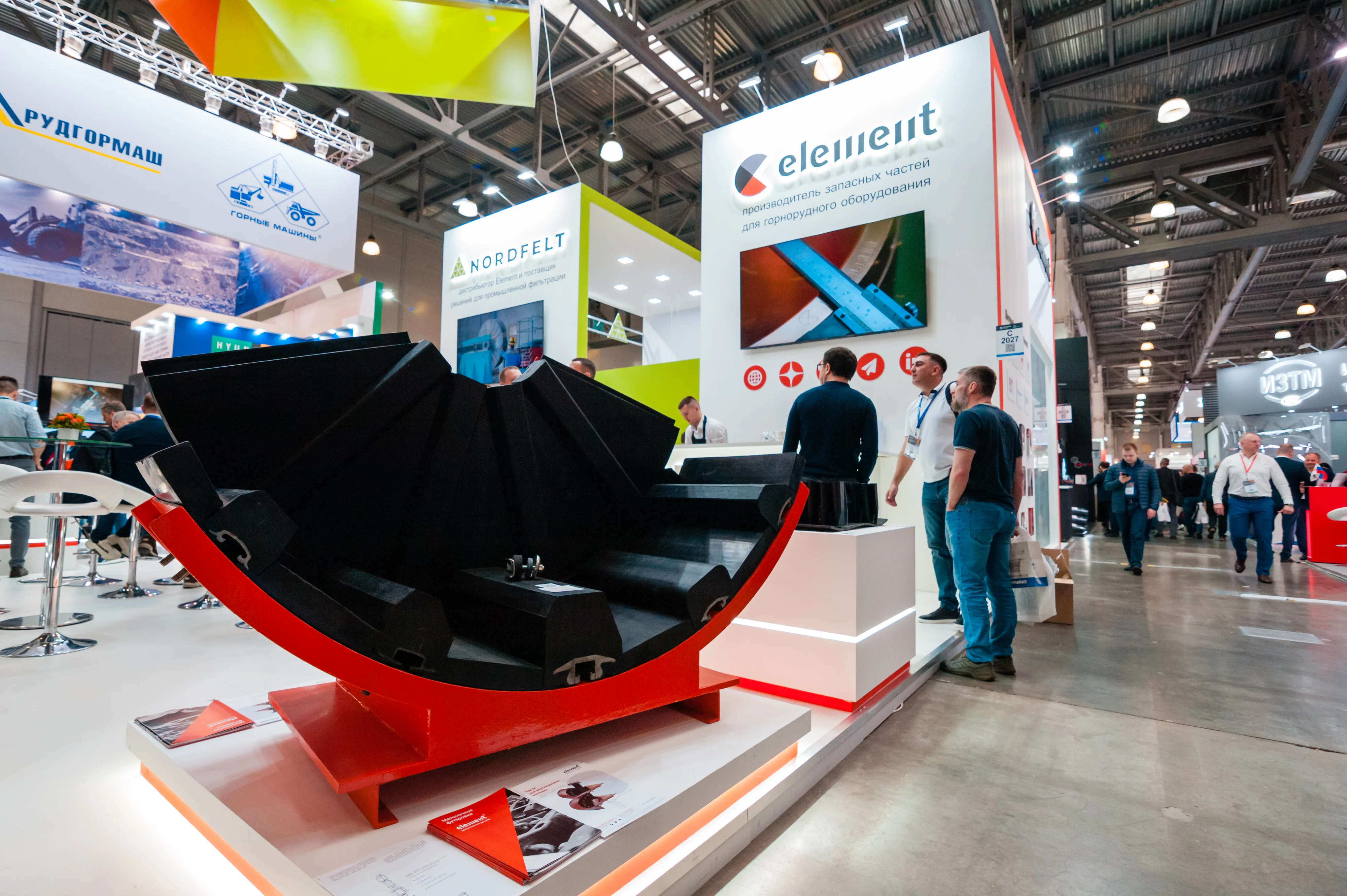

"Mining Element" will be showcasing components for underground mining equipment at MWR for the first time

At the upcoming international exhibition, Mining World Russia 2024, Mining Element will introduce products from a new line – underground mining machinery – at the stand.

Element's bimetallic linings have significantly outperformed original spare parts, lasting four times longer

Four years ago, a gravel production company installed these linings from Element, and they've since processed about 10 million tons of material. This is a stark improvement over the previous Hardox plates, which needed replacing every 12 months.

We use cookies to enhance your browsing experience, analyze site traffic and serve tailored advertisements. By continuing to browse or closing this banner, you consent to our use of cookies. Read more about how we use cookies.Cookie Policy