We produce wear and spare parts for any type of slurry pump. If the modernization of parts is needed, we can offer the "Engineering-to-order" service. All parts are manufactured using the proprietary design documentation of Mining Element.

Our specialists select various alloys and composite materials and retrofit “standard” parts to achieve the necessary performance at specific plants and applications.

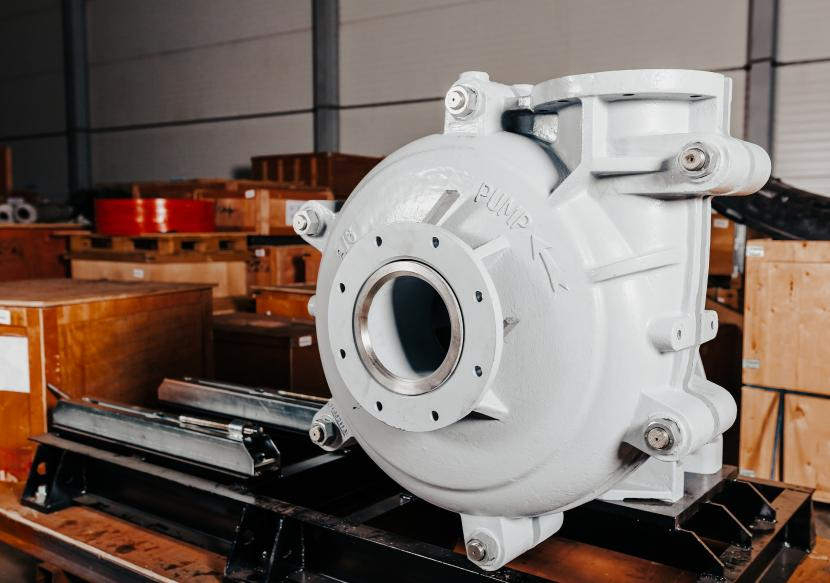

Slurry pumps transport pulp during various technological processes at mining and processing plants. Horizontal, vertical or semi-submersible slurry pumps, due to the work with solid abrasive particles, are subject to intense wear. It is necessary to regularly change both parts in direct contact with the pulp and structural parts.

Operating costs for their maintenance over several years, or even just over one year, can be equal to the initial cost of the equipment itself. For this reason, enterprises seek to reduce the cost of scheduled equipment repairs.

To solve this problem, you can buy cheap parts. However, in this case, the pumps will have to be repaired more often. High-quality parts with increased and predictable operating time ensure compliance with a stable overhaul interval and reduce the risk of emergency shutdowns, which, in turn, reduces the total cost of equipment ownership. Through the use of Element’s parts, the operating costs of enterprises are reduced by 20-30%.

The company manufactures products based on its own design documentation and in full compliance with current industry standards for safety and quality, such as ISO:9001.

Today, Mining Element is able to offer its customers about 15 thousand different products in terms of wear, spare and general industrial parts for pumping equipment from various brands. This allows us to fully meet the needs of global mining enterprises.

The company offers components for pumping equipment from brands such as:

The Element assortment includes parts for almost all models of the Warman brand, since it holds the greatest market share in Russia and abroad. The company also supplies parts for most METSO and FLS models. Mining Element’s specialists and company dealers are ready to advise on the choice of parts and their material designs to solve specific customer problems.

Thanks to many years of experience, its own design office, as well as reliable partners in the face of leading manufacturing plants in the industry, Mining Element guarantees full compatibility of the supplied parts with the installed pumping equipment. Compliance with all manufacturing standards ensures absolute compliance of the technical and operational characteristics of the supplied components with OEM parts.

Parts that are in direct contact with the transported pulp are subject to the most intense wear. Mining Element offers high-quality wear parts from various materials:

Mining Element manufactures the entire range of necessary spare parts for slurry pumps:

Mining Element offers parts for general industrial equipment involved in pumping processes: bearings, V-belts and pulleys, belts and bushings, cuffs and seals, as well as special and standard fasteners, in addition to seals of various types and other products.

The company can also order a wide range of emergency parts for pumping equipment, including covers and flanges, adjustment elements, stations and transition frames.

Mining Element manufactures parts for slurry pumps using durable and wear-resistant materials, namely cast iron and polymer compounds. They are produced both according to national standards and in accordance with the special requirements of customers. Various compositions of alloys and polymeric compounds ensure the resistance of components to the effects of abrasive rocks.

For the production of spare and wear parts for slurry pumps, we use cast iron of the following grades:

characterized by high resistance to erosion.

has a high resistance to corrosion processes in environments with a pH from 3 to 14;

has all the advantages of the previous alloy, combined with the possibility of application without heat treatment.

Equipment flow parts are made from polymeric materials, including:

ER40/ER50 natural rubbers come with high wear resistance and medium chemical resistance;

rubber based on polychloroprene CR50/CR60, highly resistant to various oils and ozone;

chlorosulfonated CSM 65 polyethylene with improved acid resistance.

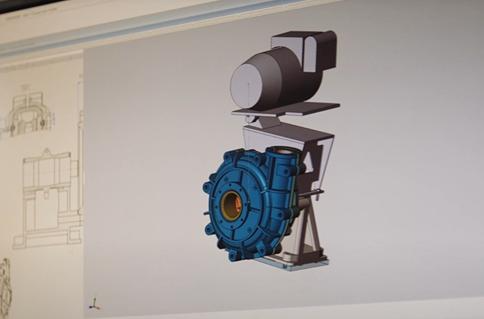

Mining Element offers not only analogues of parts from equipment manufacturers, but also products designed to meet the needs of customers. Based on the tasks of customers and the operating conditions of the equipment, the company is able to find suitable solutions to the customer's problem.

Mining Element’s technologists are tasked with selecting the optimal cast iron or rubber alloy. In some cases, Mining Element, if necessary, offers impellers with an altered diameter.

The task of individual engineering is to increase the technological or economic efficiency of the equipment. Upgraded parts allow businesses to adjust the mileage of their wear parts. Increasing the life of the part eliminates regular downtime, and therefore the need to keep a warehouse in case of an emergency pump failure.

The company can guarantee specific operating hours of slurry pump parts if requested by the customer. Each such request is subject to individual consideration, since the operating conditions of the same model of slurry pump may differ significantly.

Mining Element is ready to show the customer completed projects that clearly demonstrate the economic feasibility of using Element® products.

Based on the analysis of the base of equipment used at mining and processing plants, Mining Element and its official dealers have formed a warehouse program. Thus, for regular customers, there are always in-demand parts in stock: more than 15 thousand products for pumps of various categories and sizes, including parts for general industrial use, are available. This allows us to deliver parts to regular customers within seven days from the date of the order. The list of parts in stock is updated monthly.

In addition, we offer the possibility of concluding contracts for consignment warehouses. Mining Element can keep a stock of necessary parts in warehouses in locations convenient for the customer. Various payment options are available: conditions for consignment warehouses are discussed individually.

The company's product catalogue contains several thousand highly-regarded Warman brand slurry pump products. The part list covers 95% of models and sizes used in Russia. Most of the parts in stock relate specifically to Warman slurry pumps: more than 13 thousand items, including parts for general industry, as well as spare and wear parts for the most popular series: AH, AHF, AHE, G, L, SP, MCR.

Mining Element offers spare, wear and general purpose parts for Metso slurry pumps in the following series:

Element parts for FLS slurry pumps are always in stock, including general industry parts. The manufacturer has its own design documentation for parts, so it can manufacture parts from scratch and deliver them to the customer through a dealer. The company can order parts for MillMax, MillMax UMD and Slurry Max series pumps of all popular sizes. More often than not, Mining Element orders FLS MillMax 3x2, 6x4, 8X6, 12x10, 16x14.

We use cookies to enhance your browsing experience, analyze site traffic and serve tailored advertisements. By continuing to browse or closing this banner, you consent to our use of cookies. Read more about how we use cookies.Cookie Policy