Spare parts and components are completely interchangeable with parts of pointed equipment. Provided and produced with warranty obligations of the Element trademark. All designations, trademarks, and commercial names are mentioned on this site for informational purposes only and not for Element's product differentiation.

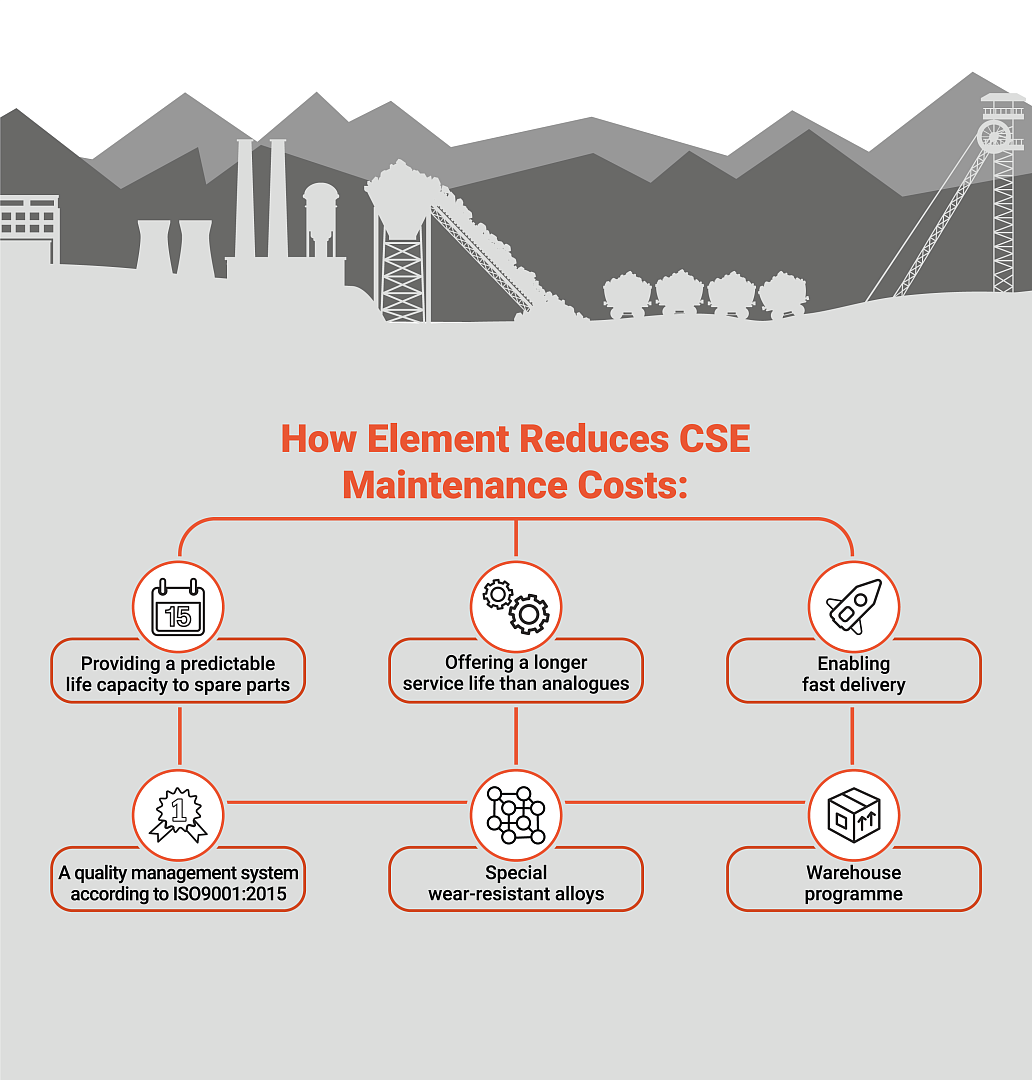

The premature wear of the spare parts of crushers leads to the shutdown of mining equipment and losses.

In some cases, downtime losses are dozens of times higher than the cost of the parts themselves. Therefore, mining enterprises tend to repair crushing and screening equipment as infrequently as possible and only when planned.

The cost of Element parts per tonne of recycled material is up to four times lower than parts from mining equipment manufacturers. Find out by how much you can increase the life capacity of the crusher linings in your company.

Mining Element’s specialists will calculate by how much you can increase the repair interval of crushing and screening equipment (CSE).

Mining Element produces spare parts compatible with most branded equipment (Sandvik®, Telsmith®, Terex®, ThyssenKrupp®, TRIO®, Zenith®, Uralmash®, etc.).

Mining Element guarantees compliance with the material of manufacture, geometric and operational parameters of the OEM. At the same time, the company gives a guarantee for operating time and also offers modification of geometry and material to order.

The Element catalogue includes more than 80 thousand names of spare parts: shafts, rings, bushings, gear mechanisms, bearings, side linings, crushing plates, bronecones, armored rings, body parts, etc.

Mining Element produces parts for cone crushers with cantilever and suspension shafts, as well as for gyration crushers of various brands.

Mining Element produces linings for the cone, bowl, arm, driveshaft, the frame, as well as distribution plates.

Components for crushers from Mining Element have guaranteed compatibility with any type of crushing equipment. They are all made of high-quality materials and the customer keeps full control of the production cycle.

THOR is a technology for modifying the structure of manganese steel. A modifier is added to the molten metal. Thanks to it, the structure features fantastic homogeneity and density. It also reduces harmful impurities and non-metallic inclusions, which increases the strength of the product.

Mining Element uses THOR technology to produce linings for jaw, cone and gyratory crushers, as well as cast wear parts for feeders.

Bushings for various purposes, annealed rings, cone nuts, sliding bearings, supports, brackets, plates, seals, gaskets, springs, conical and spherical bearings; shafts, frame parts, gears, and eccentrics.

An extensive warehouse programme: receive emergency parts within two weeks.

A complete list of available parts for your crusher offered by Mining Element’s manager:

Mining Element is able to solve two problems:

Using Element linings:

We offer standard fasteners: bolts, nuts, washers – in addition to special fasteners: wedges, clamping and supporting strips.

The side linings of the frame and the breaker plate of the movable jaw are made of manganese steel or wear-resistant steel with a high Brinell hardness.

Element TC – linings made of standard manganese steel alloys that are reinforced with titanium carbide inserts. They show higher resistance to impact loads and cracking. This effect is achieved through special casting processes and heat treatment of the end product.

During the tests, linings with inserts demonstrated an operating time that was 1.5 to 4 times more than those of classic manganese steel linings without inserts.

Rotary crushers are used at all stages of crushing and often work 24/7.

Due to the high degree of reduction in size, they are widely used in coal mining and in the non-metallic materials industry. However, with a low unit cost, rotary crushers have a rather large rate of consumption.

The use of wear parts of various geometries and alloys ensures the desired performance and characteristics of the end product in each case.

The repair of a roller crusher mainly involves the replacement of sluggers or crushing segments for rolls — the parts that tend to wear out the most within the crushing mechanism. The harder the ore or stone is, the sooner the parts will need to be replaced.

Mining Element produces wear parts for roller presses, as well as crushers with smooth, grooved and toothed rolls.

Mining Element offers spare parts for the screens and feeders of various brands on the market. Specialists will produce the necessary spare parts according to the customer's drawing or design an upgraded version at the customer's request.

Bearing housings, grizzly bars made of wear-resistant steels, (including those with bimetal surfacing), crossbeams, crossbars, springs, bearings, linings, wear-resistant plates, feet, labyrinth seals.

Horizontal screens, inclined screens, screens with multi-tilt, plate feeders, grizzly feeders, vibrating feeders, roller feeders.

Screens are made mainly of synthetic materials – rubber and polyurethane. At the request of the client, we also produce wire screens and metal panels, including special versions, for example, those that are heat-resistant.

Parts for general industrial purposes from Mining Element are produced according to DIN, ISO and GOST standards.

The range includes bearings, fasteners, V-belt gears, electrical and hydraulic components, in addition to filters.

Mining Element knows the compositions of machines used in the mining industry, therefore, parts for general industrial purposes and spare and wear parts for crushing, sorting, pumping and conveyor equipment can all be compiled in a single order.

Mining Element offers not only complete analogues of parts by equipment manufacturers, but also products designed specifically to meet the needs of customers.

Individual engineering, first of all, is designed to increase the economic efficiency of equipment. With the help of individual engineering, enterprises can adjust the life capacity of wear parts. Increasing the service life of parts eliminates regular downtime due to overfitting and the need to keep a warehouse of spare linings. In addition, parts can be modified so that installation becomes easier, and the quality of the output material is higher.

Based on the tasks of customers and the operating conditions of the equipment, we determine what to improve in a part. This is how Mining Element’s specialists select the optimal material and profile. It’s also how they provide parts that are missing from the equipment manufacturer's line.

Mining Element guarantees a specific operating time in hours or tons of recycled material, depending on the equipment and operating conditions.

Engineers can provide a justification for the payback period and show the company's implemented projects demonstrating the economic efficiency of Mining Element’s products.

Due to an analysis of the database of equipment installed at mining enterprises, Mining Element fills its own warehouses with in-demand products in order to deliver parts in the shortest possible timeframe.

If the part is in stock in Russia, the delivery time may range from several hours to a week.

If the part cannot be found in Mining Element’s warehouses, the company accepts orders for the bespoke production and delivery of parts.

Order spare parts for crushers or screens using the form below, and we will contact you within two days. You can attach a drawing or a completed questionnaire for CSE parts to the application: this will speed up the preparation of a quote for you.

We use cookies to enhance your browsing experience, analyze site traffic and serve tailored advertisements. By continuing to browse or closing this banner, you consent to our use of cookies. Read more about how we use cookies.Cookie Policy