Compatibility with equipment

Compatibility with equipment

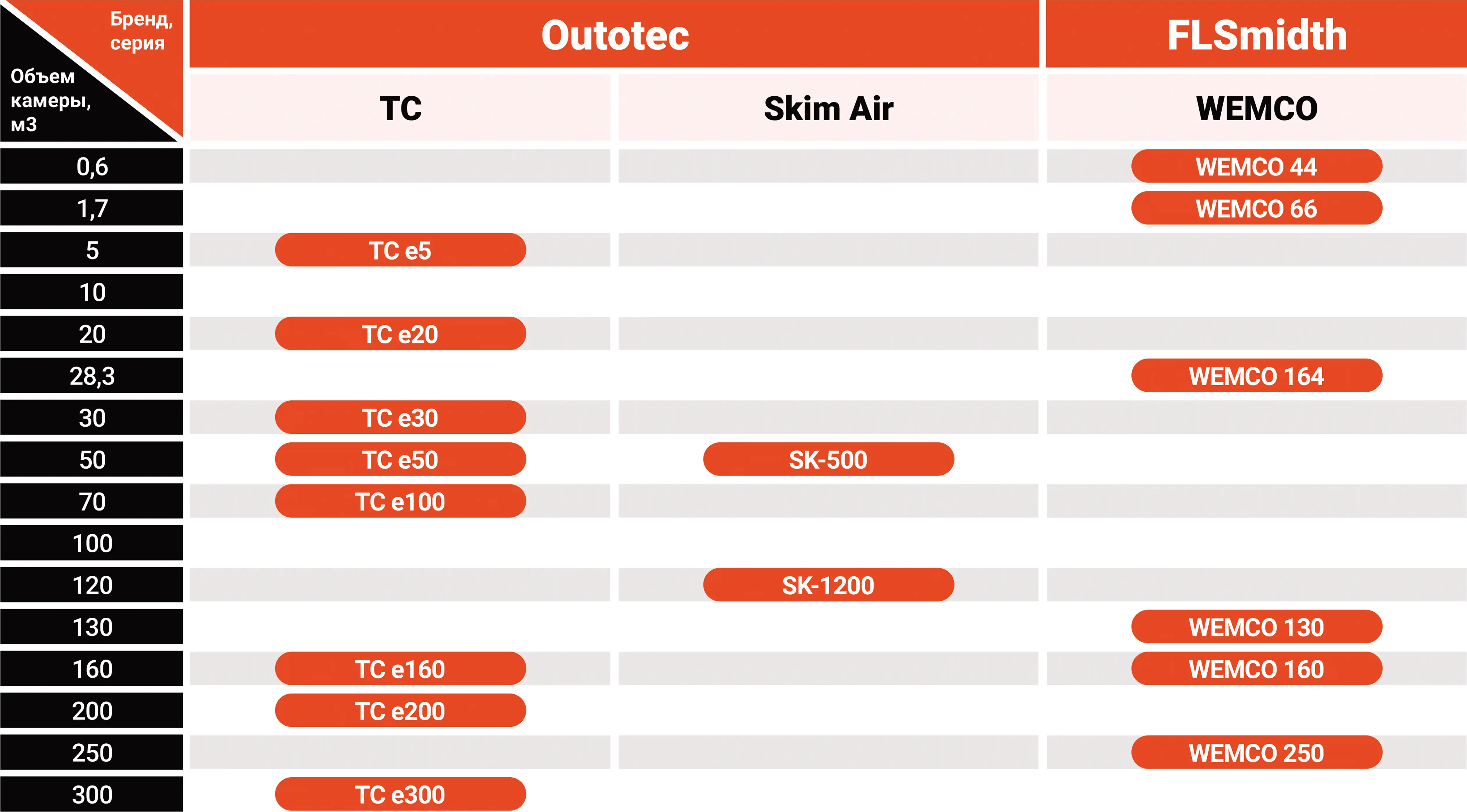

Wear parts for flotation machines

Wear parts for flotation machines

Wear parts for gravity concentrators

Wear parts for gravity concentrators

Wear parts for hydrocyclones

Wear parts for hydrocyclones

The range includes:

- Wear parts: liners (cone, cylinder, cover), spigots (apexes) and vortex finders (overflow tubes), adapters.

- Spare parts: cones, cylinders, inlet chamber, cover, clamps.

- Manufacture in steel, cast iron, or polymers depending on service conditions.

Materials of construction

We use proven materials that extend equipment service life. The options for wear-part execution are listed below.

Design and engineering

Mining Element’s design department prepares complete technical documentation. We design and build detailed 3D models of flotation machines, hydrocyclones, and gravity concentrators, with special attention to assemblability and to matching overall and connection dimensions.

Mining Element offers customised solutions on request. The process starts with collecting the client’s technical requirements and preferences. Based on this information, our engineers prepare design documentation, agree the project with the customer, and launch production.

Advantages of Element’s wear parts

Advantages of Element’s wear parts

Service-life assurance – extended wear life through optimal material selection.

Regular deliveries – scheduled supplies aligned with your plant’s planned maintenance calendar.

Value – optimal price-to-performance ratio with an individual approach to every order.

Engineering support – creation of 3D models to verify compatibility.