Spare Parts for Vertical Shaft Impact (VSI) Crushers

Download Brochure

Spare Parts for Vertical Shaft Impact (VSI) Crushers

Vertical shaft impact (VSI) crushers (also called centrifugal crushers) use a stone-on-stone impact principle to produce fine, cubical product. They are most often used at the third and fourth stages of crushing.

Although VSIs offer a low specific operating cost, they have comparatively high consumption of wear parts. Mining Element supplies VSI parts for most brands in the industry and delivers components that are fully compatible with the required equipment models.

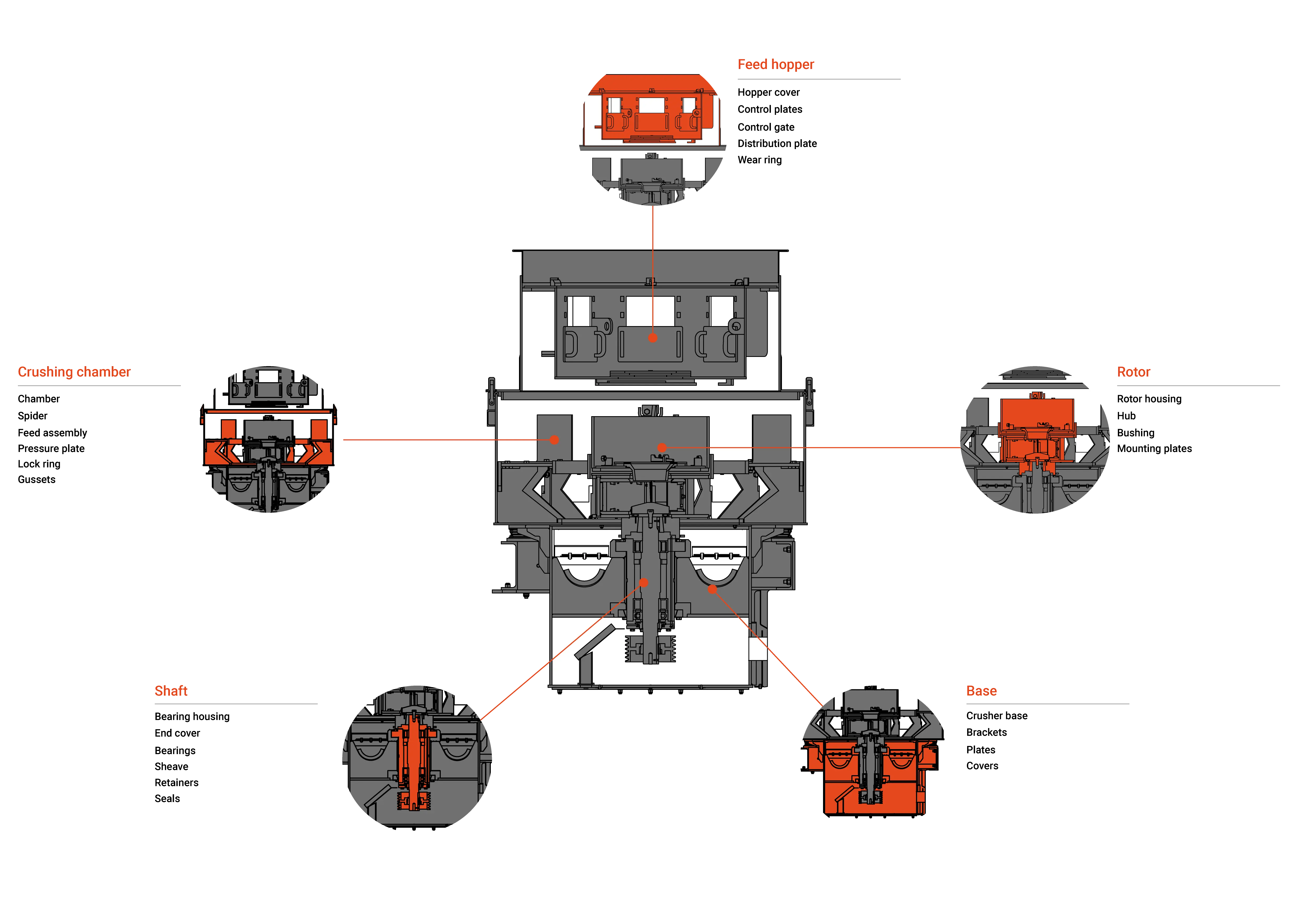

Assortment of Parts

Depending on the crusher design, typical VSI wear parts include: liners and rotor tips with back-up tips, upper and lower wear plates, distributor (distribution) plate, profile/side plates, feed tube (inlet pipe) and loading ring, throwing shoes/accelerator blades, anvil ring and anvils, other chamber and rotor protection elements,

The most wear-sensitive items are the liners and rotor tips/back-up tips. Mining Element manufactures these from steel fitted with three types of tungsten-carbide inserts.

Selecting the right geometry and alloy for the application ensures the required throughput and final product characteristics.

In addition to wear items, timely replacement is also required for bearings, seals, V-belt drive parts, and other mechanisms and components. Mining Element’s comprehensive offer covers standard catalogue products as well as components manufactured to individual drawings or sketches.

Advantages of Working with Mining Element

- Complete solutions. The catalogue includes the full range of spare and wear parts for vertical shaft impact crushers.

- Individual engineering. With many years of experience in repair, operation, and complex engineering tasks, we supply not only standard options but also products adapted to specific operating conditions. Our in-house design department prepares all necessary technical documentation.

- Warehouse program. To promptly meet customer needs, we maintain stock and provide technical consultants who understand machine design and crusher spare-part selection.

- Guarantees. Technical support is provided throughout the entire service life of the products. Warranty support is included in the price.

- Efficient logistics. If the part is in stock, we ship it on the day the order is placed. If it is not in stock, typical delivery is 120–150 days. In case of an accident and unplanned downtime, we will arrange urgent, emergency delivery options to restore the line.

For consultations or to order spare parts, email pro@miningelement.com or use the phone numbers listed on our website.