Mining Element Expands Its Offerings: Looking back at 2023

Mining Element Expands Its Offerings: Looking back at 2023

In the past year, Mining Element has significantly expanded its product range to nearly 120,000 items. This expansion includes not only additions to existing product lines but also a new category for the company: Underground Self-Propelled Equipment. Additionally, the opening of a new warehouse in the Far East, major projects to upgrade wear parts, and nearly eight months spent by our designers at Russian mining sites have brought us even closer to our clients.

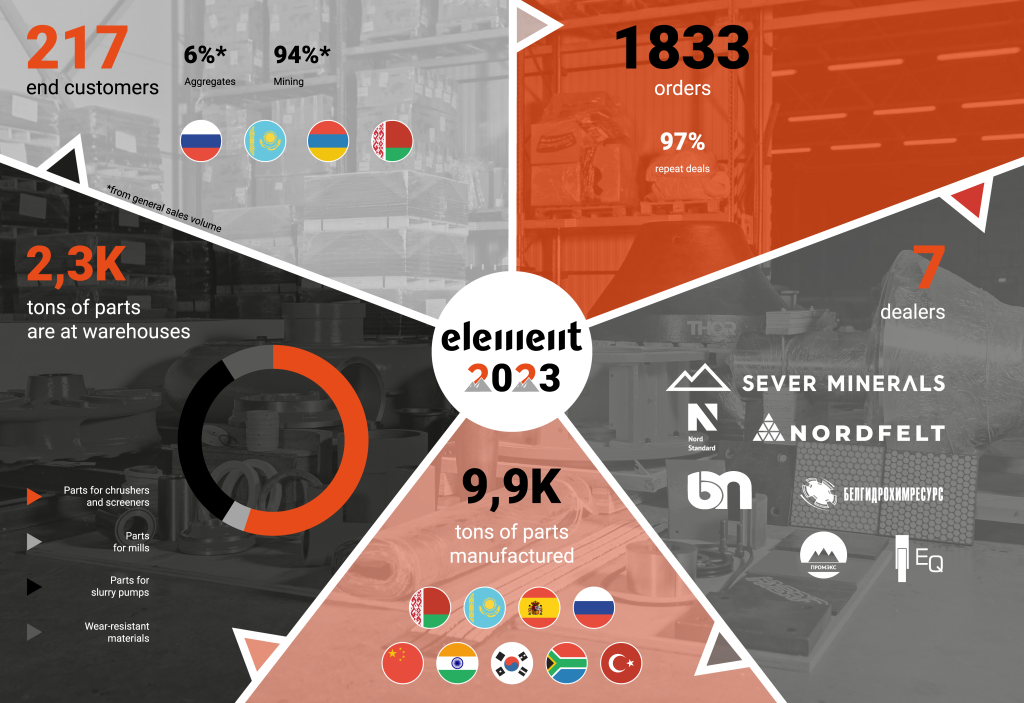

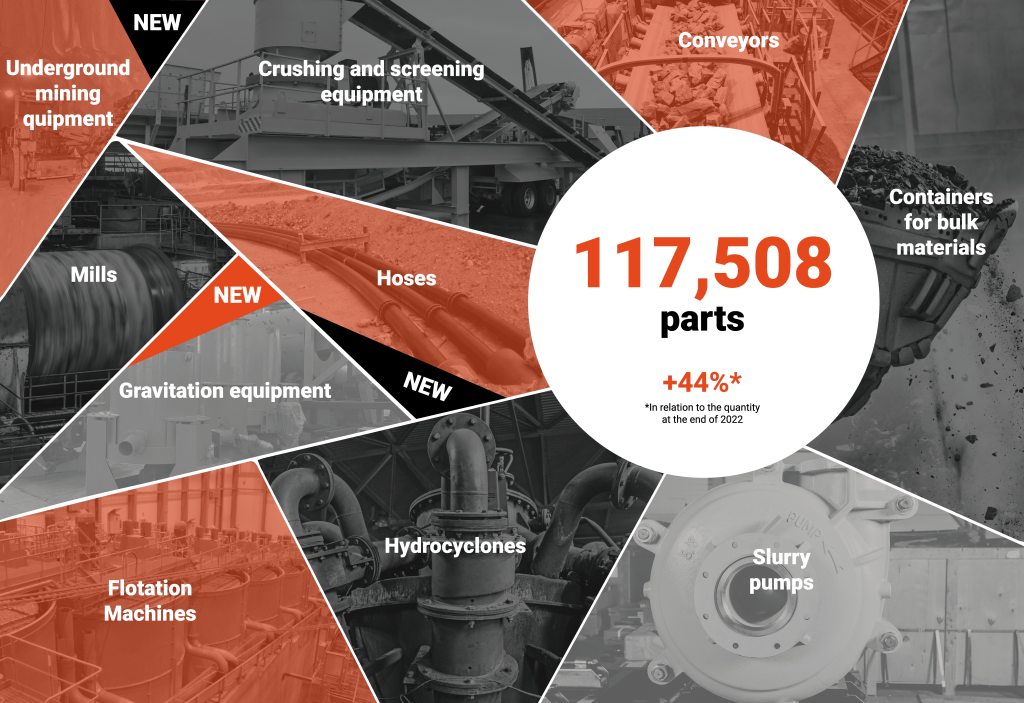

Each year, we take stock of our growth as a company. This year, we successfully expanded our product assortment significantly. Mining Element increased its range by 44%, adding 117,000 different spare, wear, and industrial parts. Now, our company can supply components for equipment used in not just crushing, transport, milling, and enrichment processes, but also in extraction.

Marat Abdurakhimov, Development Director at Mining Element, emphasised that the company's aim is to meet the parts needs at every stage of production.

"Our offerings will continue to grow. As our customer base evolves and new brands emerge, we adapt quickly to support enterprises with reliable spare parts. Many new brands aren't seriously committed to supplying their own equipment, and that's where we step in," he explained.

Element and production

Preparations for launching this new direction began back in 2022 when it became clear that mining enterprises needed to find new suppliers of parts for dump trucks, loaders, drilling rigs, and auxiliary equipment in the near future.

In 2023, the first results of this effort emerged: the catalogue currently includes nearly 30,000 parts, including hinge joints and fasteners, hydraulic perforators and their spare parts, internal combustion engine components, drilling module components, seals and repair kits, cooling systems, transmissions and axles, hydraulic components, electrical equipment, and consumables.

In 2023, production commenced, and Element hydraulic perforators and pumps are already in stock in Russia, ready for immediate use.

Element’s new classifications

In 2023, the company began selling components for gravity concentrators. At present, Mining Element produces the most wear-prone parts: the concentration cone (basket), deflector, and lower cone. Additionally, since 2023, the company offers screens for ultra-fine screening.

Meanwhile, the product line from 2022 – wear parts for flotation machines – has entered mass production. In 2023, the company manufactured and delivered over 20 sets of aeration units for Outotec brand flotation installations of three series: TC 20, 50, and 100.

Another innovation is slurry pipelines. We supplied large-diameter pipes of 300 and 400 mm for the route from the pump to the hydrocyclone at one of the mining enterprises.

Transportation at Element

At the "Coal of Russia and Mining 2023" exhibition, our company introduced a unique product for the Russian market – a fire-resistant belt with a solid woven carcass. Such products are indispensable in production areas requiring a high level of fire safety, such as coal mines, power stations, and beneficiation plants.

Furthermore, one of our official dealers have, for the first time, supplied Element-brand pipe belts to one of Russia's iron ore plants. In August, they were installed, and they are now continuing to transport cemented iron ore pebbles.

Several conveyor components have been added to the available order list, including a chain table and conveyor drum. An Element-brand product from 2022 – the conveyor roller – was sold in quantities exceeding 5,000 units to just one enterprise.

Element and Wear Protection

The portfolio of wear-resistant solutions for bulk material handling and transfer devices has expanded significantly. This includes rubber with magnets, steel with tungsten carbides, cast iron with ceramics, wear-resistant cast iron on a steel base, and mill lining. Each of these products is designed for specific operating conditions, allowing for equipment wear to be levelled and significantly slowed down. Rubber with magnets and wear-resistant cast iron on a steel base have already undergone successful trials at enterprises.

Thanks to the intensive generation of new products, the "Golden Idea of the Year" award from the Women in Mining awards was received by Olga Stepuk, the head of the Wear-Resistant Materials department.

CHRON: Rapid Mill Lining Replacement

Mining Element has released a unique product for the Russian market – CHRON. This is a rubber-metal lightweight lining for MSI and MPSI mills with a simplified fastening system, reducing part replacement time by up to 40%.

At the copper-nickel ore processing plant, the lifespan of the CHRON set exceeded the guaranteed service life, and the lining, in general, outlasted the metallic one by 25%.

Demand for Reverse Engineering

The core competency of Mining Element has always been engineering. Predictably, there was a significant demand for reverse engineering in the past year, as many new equipment brands have entered the market, and not all of them have uninterrupted access to suitable and high-quality components.

The core competency of Mining Element has always been engineering. Predictably, there was a significant demand for reverse engineering in the past year, as many new equipment brands have entered the market, and not all of them have uninterrupted access to suitable and high-quality components.

A team of 20 engineering designers from our department embarked on business trips across the country, collectively spending 30% of their time on these endeavours. During their travels, they scanned several hundred components and developed almost 2,000 sets of engineering documentation.

Among the large-scale components they designed, there are 40 projects related to mills, including rare vertical ones. They also created products for 123 models of pumps, encompassing wear-resistant flow parts and bearing assemblies.

In the category of Crushing and Screening Equipment (CSE), our design team developed components for 116 different equipment models, ranging from cone crushers to plate feeders.

Element and Customization: More Than Just a Manufacturer

Mining Element is expanding not only its product range but also its services. Customising components for crucial technological nodes has always been an option for our customers. However, this year, the company proactively offered solutions to optimise production processes and enhance their efficiency.

"Everyone is focused on enhancing enterprise efficiency. People want to streamline their processes and strive for efficiency. Obvious methods of productivity improvement and cost reduction have already been explored. It's time for more complex projects where each additional percentage of efficiency requires a deep dive into the essence of the problem. There are areas that demand expertise, experience, and reliable partners, and that's where we offer something that sets us apart from other manufacturers," commented Marat Abdurakhimov, Director of Development.

For a Russian iron ore MPP (mining and processing plant), Mining Element developed a new design for the crusher MK6089's mantle. The product size at the crusher's output was excessively large, causing significant issues for loading stations and conveyor belts. To reduce the size of the discharge gap, product specialists proposed altering the geometry of the lower row of the mantle by increasing the segment thickness and shifting the centre of the mantle circle downwards by 80-90 mm. This adjustment achieved the optimal ore size at the crusher's output for further transportation without significant damage to loading stations and conveyor belts.

"We have long mastered the high-quality reproduction of parts of any complexity, but there is always room for improvement. This is our next level. By listening to the customer's needs, we fine-tune products individually. Logically, this is the next step in the growth of our capabilities," concluded the director.

Element and Availability

Mining Element continues to expand its warehouse program to ensure prompt deliveries to its regular customers. This year, the company has opened its third warehouse in Russia, this time in Vladivostok. The new warehouse primarily stores or prepares for shipment over 200 tons of wear parts and other components for slurry pumps, as well as a variety of crusher spare parts.

Element parts occupy more than 3,000 square metres and weigh 2,260 tons. The majority of them are intended for slurry pumps and crushing equipment. In addition, Element continues to stock industrial parts from global brands such as Timken and SKF to supply them as part of its product packages.

But Mining Element's service doesn't stop there. The company enters into consignment agreements with its regular customers. For slurry pumps alone, this year, the company placed over 100 tons of hydrotransport spare parts in consignment storage at customer facilities.

Element’s 2024

"In 2024, Mining Element aims to get even closer to its customers, offering a broader range of services in addition to an expanded product assortment. When referring to services, the Director of Development means customization of spare parts, on-site technical support including consultations, audits, diagnostics, identifying customer needs, and generating solutions to urgent problems. The company will also provide mandatory warranties for fit and compatibility with equipment.

We are pleased when customers, in their quest for safety, invite us for reverse engineering even with new equipment. We encourage preparing for the operation of new machines in advance. After all, new equipment is often poorly supplied with components, and it's not perfect. We offer solutions for the existing equipment base that our customers operate and are ready to be reliable partners for them," concluded Abdurakhimov.

We use cookies to enhance your browsing experience, analyze site traffic and serve tailored advertisements. By continuing to browse or closing this banner, you consent to our use of cookies. Read more about how we use cookies.Cookie Policy